Exploring the heart of a company’s operations can provide invaluable insights into its processes, values, and commitment to quality. Recently, members of the GBP Direct team had the privilege of embarking on such an adventure by visiting the manufacturing plant of Global, a leading name in the industry renowned for its innovative furniture solutions. This journey offered a firsthand glimpse into the intricate workings of Global’s production, from textile cutting to product testing facilities, leaving a lasting impression on all who attended.

Product Testing Facility:

The team’s journey began with a tour of Global’s state-of-the-art product testing facility. Here, they witnessed rigorous tests designed to ensure the durability, safety, and performance of each piece of furniture. From stress tests to durability assessments, every product undergoes meticulous scrutiny to meet the highest standards. Witnessing this process firsthand underscored the company’s unwavering commitment to delivering superior quality and reliability to customers.

Textile Cutting and Sewing:

Next on the itinerary was a visit to the textile cutting and sewing department. Here, skilled artisans meticulously crafted upholstery pieces with precision and care. Witnessing the craftsmanship firsthand highlighted the attention to detail and craftsmanship that goes into every Global product. From selecting the finest materials to sewing each seam with precision, the dedication of the team was palpable, ensuring that each piece meets the company’s exacting standards for quality and aesthetics.

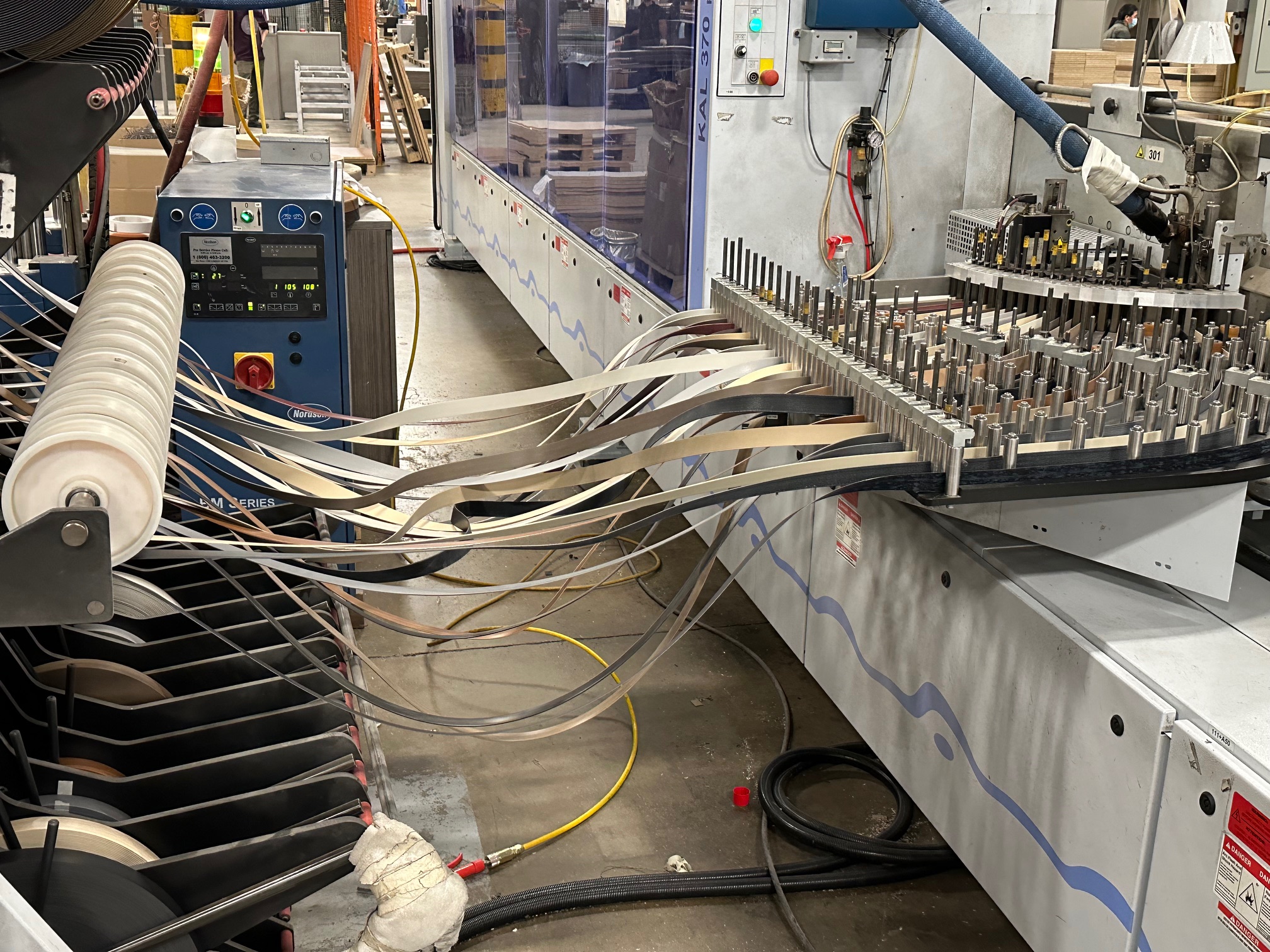

Laminate and Veneer Plants:

The tour then led the team through Global’s laminate and veneer plants, where raw materials are transformed into exquisite finishes that adorn their furniture pieces. Cutting-edge technology and expert craftsmanship converge to create stunning laminates and veneers that enhance the visual appeal of each product. Seeing the transformation process from raw materials to finished surfaces underscored the company’s commitment to innovation and sustainability, utilizing eco-friendly practices to minimize environmental impact.

Plastics Recycling Plant:

In addition to exploring Global’s manufacturing processes, the GBP Direct team had the opportunity to visit the plastics recycling plant, a testament to Global’s commitment to sustainability and environmental stewardship. Here, they witnessed firsthand the transformation of recycled plastics into components used in their furniture products. This innovative approach not only reduces the company’s carbon footprint but also minimizes waste and promotes a circular economy.

Seeing the plastics recycling plant in action highlighted Global’s dedication to incorporating sustainable practices into every aspect of their operations. By repurposing discarded plastics and giving them new life as components for their furniture pieces, Global is not only reducing the demand for virgin materials but also contributing to the preservation of natural resources. This sustainable approach resonated deeply with the GBP Direct team, reinforcing their own commitment to environmental responsibility and inspiring them to explore similar initiatives within their own supply chain.

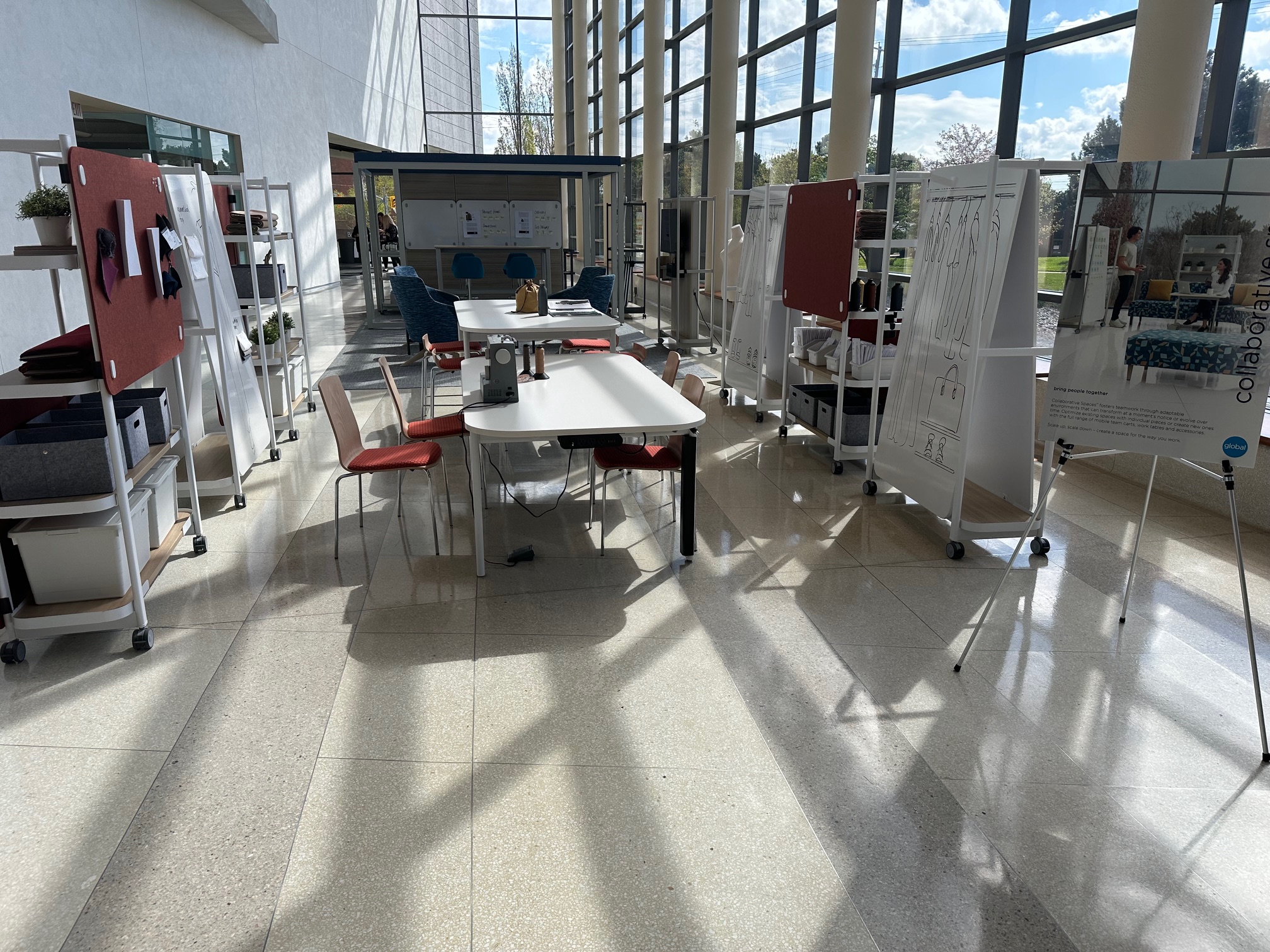

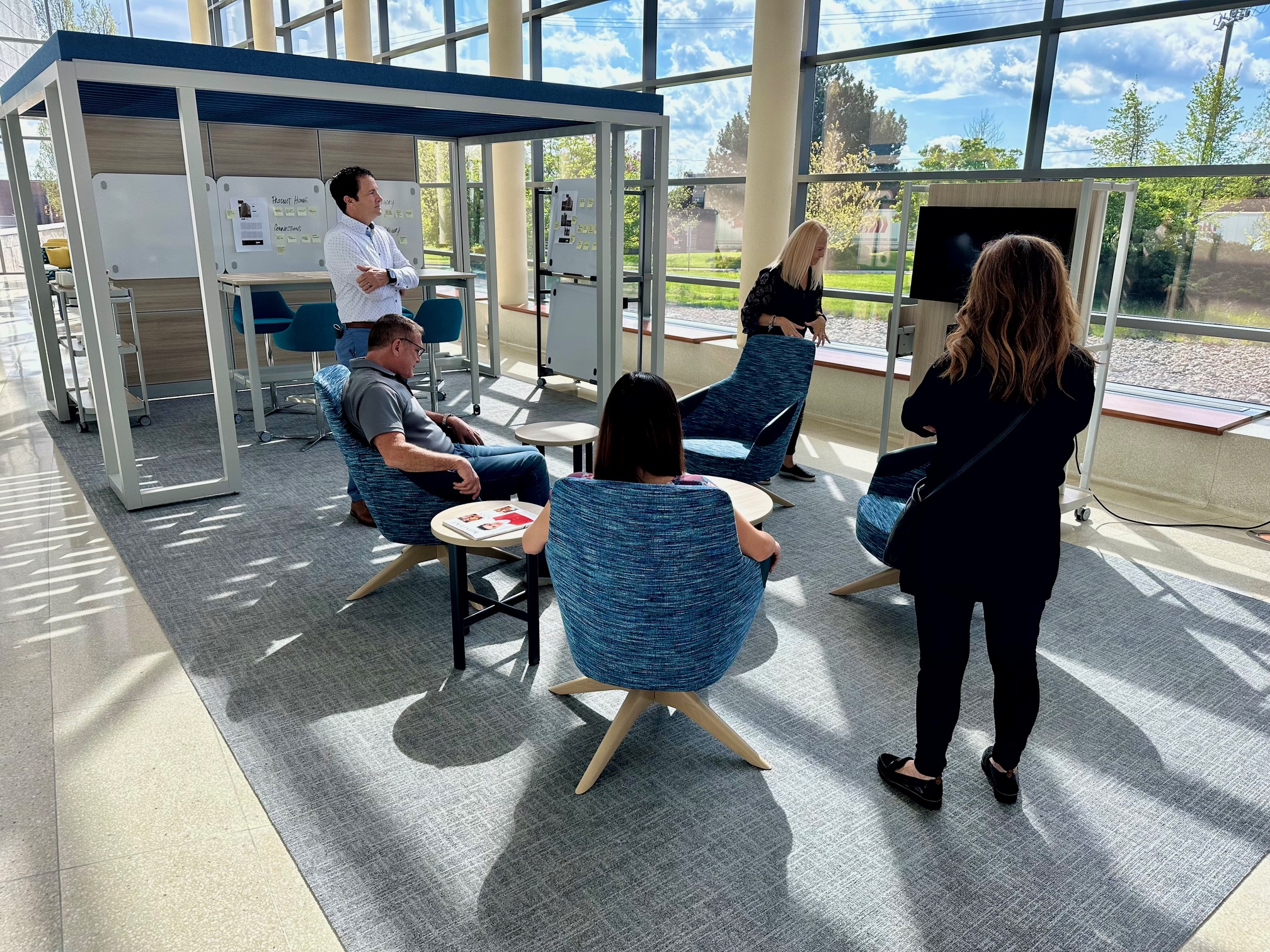

Product Showroom:

The journey culminated in a visit to Global’s product showroom, where the team had the opportunity to experience the breadth and depth of the company’s offerings firsthand. From sleek office furniture to ergonomic seating solutions, the showroom showcased Global’s dedication to blending form and function seamlessly. Exploring the diverse range of products served as a source of inspiration for the GBP Direct team, offering new ideas and perspectives to enhance their own offerings and better meet the needs of their clients.

The visit to Global’s manufacturing plant was not only an educational experience but also an inspiring journey that left a lasting impression on the GBP Direct team. From witnessing the meticulous craftsmanship to gaining insights into the company’s values and processes, the tour provided invaluable lessons and inspiration that will undoubtedly shape the team’s future endeavors. Armed with newfound insights and inspiration gathered from their immersive experience at Global’s manufacturing plant, the GBP Direct team eagerly set their sights on the Louisiana furniture market. With a fresh perspective on the importance of quality craftsmanship, sustainability, and innovation, they were prepared to showcase their enhanced product offerings and forge stronger connections with local retailers and consumers alike. Armed with stories of Global’s commitment to excellence and sustainability practices, the team approaches the Louisiana furniture market with confidence, knowing that they were are to make a meaningful impact and elevate the standard for furniture solutions in the region.